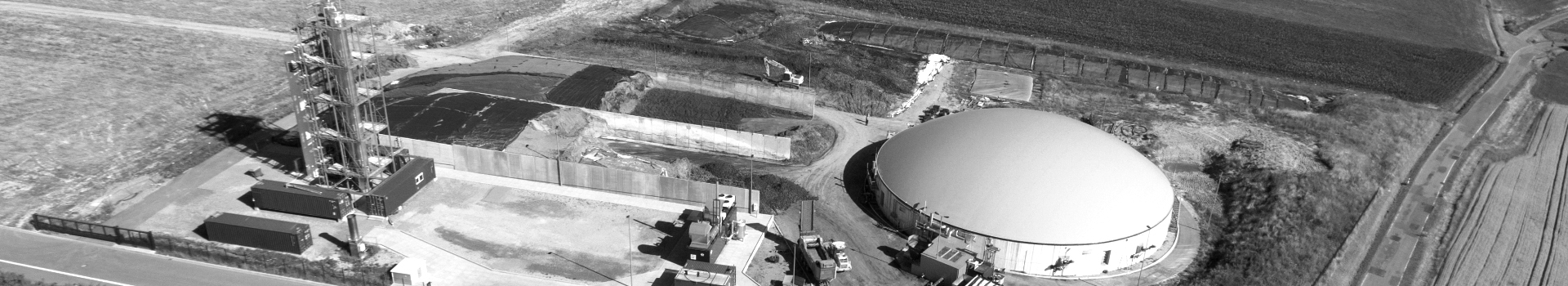

Biorefinery at Pirmasens-Winzeln Energy Park

PFI’s Research Plant Department develops and operates pilot plants at the Energy Park. In the course of the next few years, these plants will be expanded to a biorefinery for material and energetic cascade utilisation of agricultural biomass. The Energy Park is a joint project of PFI, the City of Pirmasens, and the Municipal Utility Company of Pirmasens. The following individual plants currently occupy the site:

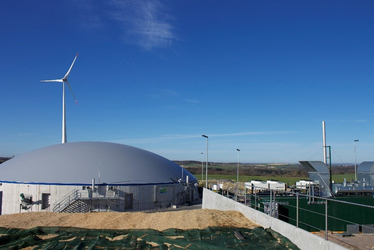

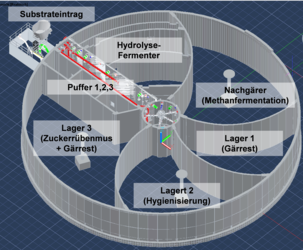

1. Nawaro Biogas Plant (2013/14)

Nawaro stands for nachwachsende Rohstoffe or renewable raw materials. In the construction of the biogas plant, PFI’s research results were implemented in a unique process-optimised multichamber system with excellent thermal insulation and additional heat recovery from the generated biogas by means of a high-temperature heat pump. These features permit acceleration of the biogas process and a significant reduction in the external thermal energy required for heating the fermenter.

Technical description: Biogas plant with silage clamp (7,890 m3), pre-hydrolysis (1,120 m3), fermenter (1,574 m3), substrate/digestate storage I (942 m3), substrate/digestate storage II (1,548 m3), substrate/digestate storage III (1,890 m3), 3 storage buffers (100 m3), CO2 heat pump (60 kWth), cogeneration unit 550 kWel.

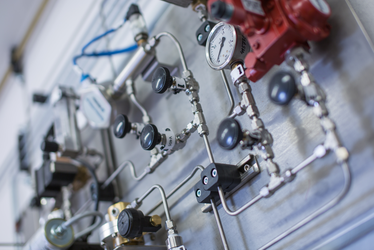

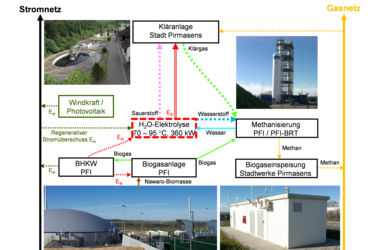

2. Biogas Upgrading Plant for Biotechnological Methanation (2015/16)

In PFI’s new approach to biogas upgrading, the carbon dioxide is not removed from the biogas. Instead, hydrogen is added to the biogas where it reacts with the carbon dioxide in the presence of microbes known as archaea to form methane. The gas is subsequently desulphurised over activated charcoal and dried by an adsorption dryer. The nutrient medium and water are recovered by a sophisticated recycling system.

Technical description: Biogas Upgrading Plant for Biotechnological Methanation 2 x 40 m3 columns up to 7 bar operating pressure; biogas upgrading for feeding in 100 Nm3/h with dew point –40 °C, water recovery 80 l/h on ceramic filters and membrane distillation for nutrient regeneration.

3. Biogas Feed-in into the Gas Grid of Pirmasens Municipal Utility Company (2016/17)

With planning support from PFI-Bioraffinerietechnik GmbH, the Pirmasens Municipal Utility Company built a feed-in unit for PFI’s biogas/synthesis gas, which monitors the gas quality according to Guideline G260/G262 issued by DVGW (German Technical and Scientific Association for Gas and Water) and adjusts the calorific value with LPG.

Technical description: Feed-in rate 20–700 Nm3/h into the medium pressure grid at 750 mbar, propane/butane conditioning to raise the calorific value to 11.2 kWh/Nm3, gas recycling in the switch-off matrix in the event of non-compliance with gas quality standards.

Construction of the Following Plants is Planned for the Future:

4. Water Electrolysis Unit Connected to Sewage Works (planned for 2018/19)

Excess electrical energy generated from renewable resources can be stored to the extent of 80 % in the form of hydrogen produced by electrolysis of water. In order to supply hydrogen for biotechnological methanation in PFI’s biogas upgrading plant and to utilise the oxygen produced by electrolysis and the waste heat for the Felsalbe sewage plant, a water electrolysis plant in Pirmasens Energy Park is to be connected by a 1,475-m pipeline system to the Felsalbe sewage plant. The aim is to achieve a maximum degree of energetic integration and to offer a practical demonstration of its feasibility.

Technical description: Water electrolysis utilising excess electrical power (1.8 MWel) Hydrogen generation 400 m3/h for upgrading of gas from sewage plant, oxygen generation 200 m3/h for aeration in activation tanks, heat supply 360 kWth for drying of sewage sludge.

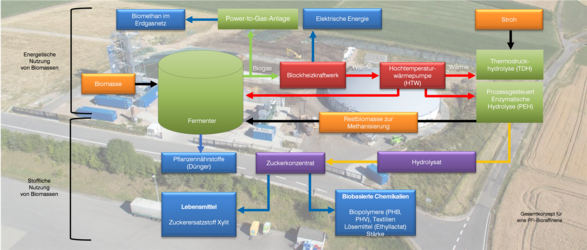

5. Straw Digestion Plant with Fermentation Centre (planned for 2020/21)

A further expansion step on the way to completion of the PFI biorefinery concept is the utilisation of straw as a substrate for biogas production (instead of maize as is currently used) and fermentation of the resulting sugar hydrolysates to form target products such as polyhydroxyalkanoates and polylactic acid (bioplastics), xylitol (sugar substitute), succinic acid (platform chemical), butanol (fuel), etc. These substances are to be produced on a pilot scale and upgraded and conditioned for their respective uses.